Recent Developments in IC Engine

RECENT DEVELOPMENTS IN IC ENGINE

Internal combustion engine efficiency has historically been limited more

by the state of technology than innovation. As an example, the potential of

technologies such as gasoline direct injection were known and attempted in

production more than 50 years ago, but direct injection has only become widely

available in production within the last decade and now makes up approximately

38 percent of new light-duty vehicle sales. Another example is low-temperature

combustion modes such as homogeneous charge compression ignition combustion—in which

fuel and air are injected during the intake stroke and then compressed until

the entire mixture reacts spontaneously—which were demonstrated in a laboratory

more than 30 years ago but are still many years away from market introduction.

Game-changing advances in recent years are improvements in engine

technologies, sensors, and onboard computing power. This combination of

technologies will enable unprecedented control of the combustion process, which

in turn will enable real-world implementations of low-temperature combustion

and other advanced strategies as well as improved robustness and fuel

flexibility. In fact, technological advances are blurring our historical

distinction between spark-ignition and compression-ignition engines; we will

see new engine concepts that blend the best characteristics of both engine

types to push the boundaries of efficiency while meeting stringent emissions

regulations worldwide.

The push toward higher-efficiency engines will alter exhaust

temperatures and chemistry and may create challenges for emission control

technologies.

For example, new higher-efficiency engines will have lower exhaust

temperatures, due to more efficient work extraction at the piston. Lower

exhaust temperatures will, in turn, require the development of new emission

control technologies, which must not only be effective at low temperatures but

also must survive high exhaust temperatures encountered under high load

conditions.

Nowadays, the main objectives are the minimization of

fuel consumption/CO2 emissions and the mitigation of exhaust

pollutants. To this aim, various alternative combustion techniques have been

developed, or are under development (e.g., direct injection SI engines, HCCI

operation etc.); various internal and after-treatment exhaust measures are also

being examined.

One particular aspect of (automotive) engines is

dynamic operation, which is responsible for the largest number of emitted

pollutants. Acknowledging this fact, the certification (both driving and

engine) cycles for all kinds of vehicles are highly transient.

Another significant aspect of modern engines is their

supercharging, realized mainly through various turbocharging configurations.

Today, turbocharging an I.C. engine is a well-established means for achieving

lower CO2 emission targets, as is also the use of hybrid

electric powertrains.

GM is also

increasing its attention to what it calls "opportunity-type"

controls. For example, using start/stop technology to stop the engine at idle

and seamlessly restart it when the brake is released, and advanced battery

charging that helps to charge the battery from regenerated vehicle kinetic

energy.

For Chris

Cowland, director, advance and SRT powertrain engineering at Chrysler,

optimization of existing combustion, thermodynamic, and gasoline exchange

technologies, as well as improving mechanical processes, will increase the

overall efficiency of the ICE.

1. Turbocharger (TDI- Turbocharged Direct

Injection): These are

nothing but turbines which are operated by engine exhaust gases to produce

power for a compressor which is in turn used to increase the mass flow rate of

air, which is sucked inside during the intake stroke. This method, increases

the power and performance of an IC engine.

2. Gasoline Direct Injection (GDI) : This method is often used in Gasoline

engines. As the name indicates, it involves the direct injection of Gasoline

into the combustion chamber of an engine by means of electrically controlled

actuators and sensors. This method helps in metering the quantity of the fuel

injected, based on our requirements thereby reducing fuel consumption.

3. Variable Valve Timing (VVT): This method involves the electronic

control of valves, thereby adjusting the valve opening and closing mechanism

based on our needs. This technology also improves fuel efficiency and

performance.

4. Common Rail Direct Injection (Crdi): This method is often used in Diesel

engines to control and maintain the effective usage of fuel under different

conditions. It consists of a common rail, were the fuel accumulates and then

supplied to the cylinders through high pressure injectors.

5. Start- Stop Technology: This method is used to stop the

vehicle when it is idle for a long period of time. i.e during traffic. This

helps in reducing fuel consumption. Now, to start the vehicle, it is enough to

hold the clutch. This method also reduces emissions.

6. Catalytic Converters: Today, due to the stringent emission

norms, after treatment devices are necessary to bring down the emissions in an

IC engine. Catalytic converters are one of the devices which reduces the

emissions from IC engines, thereby making them to comply with the emission

standards.

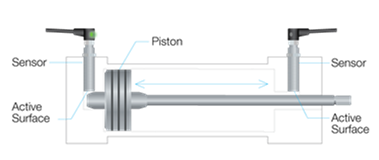

8. Cylinder pressure sensing: The pressure inside the cylinders is monitored and is maintained at required conditions. Accordingly, the turbocharger is made to function.

9. Dilute combustion: Nowadays, the fuel is diluted by passing more air than usual in it. This makes the fuel lean and reduces emission.

1.

7

Cylinder deactivation

· Cylinder deactivation is one of the technologies

that improve fuel economy. Its objective is to reduce engine pumping losses

under certain vehicle operating conditions

· It is the method of deactivating the cylinders as

per power requirement of engine to achieve better fuel efficiency. It also

helps in emission control.

· It works because only a small fraction of an engine’s peak horsepower is needed to maintain cruising speed.

Advantages

• Lean combustion

• Cleaner combustion

• Compatibility

• Easy fuel burning

• Throttle less induction

Disadvantages:

• Engine balancing.

• Increased cost of manufacturing.

• Overall increase in weight.

• Complexity of system makes maintenance difficult.

Direct fuel injection

In this method, fuel is directly injected into the

cylinders and is not mixed with air in the inlet manifold or inlet ports before

drawing into the cylinders.

Types of DIs:

• MPFI Engine (Multi Point Fuel Injection system): In this system each cylinder has number of injectors to supply/spray fuel into the cylinders.

• CRDI Engine (Common Rail Direct injection

system): In this system, all the injectors are supplied by a common fuel supply

line or a manifold called the common rail.

Advantages

· Difference in power developed in each cylinder is

minimum. Noise and Vibration from the engine is less.

· Accurate A/F mixture supplied resulting in complete combustion leading to effective utilization of fuel supplied and hence low emission level.

Disadvantages of direct fuel injection

· complexity and cost.

·

Direct injection systems are more expensive to

build because their components must be more rugged.

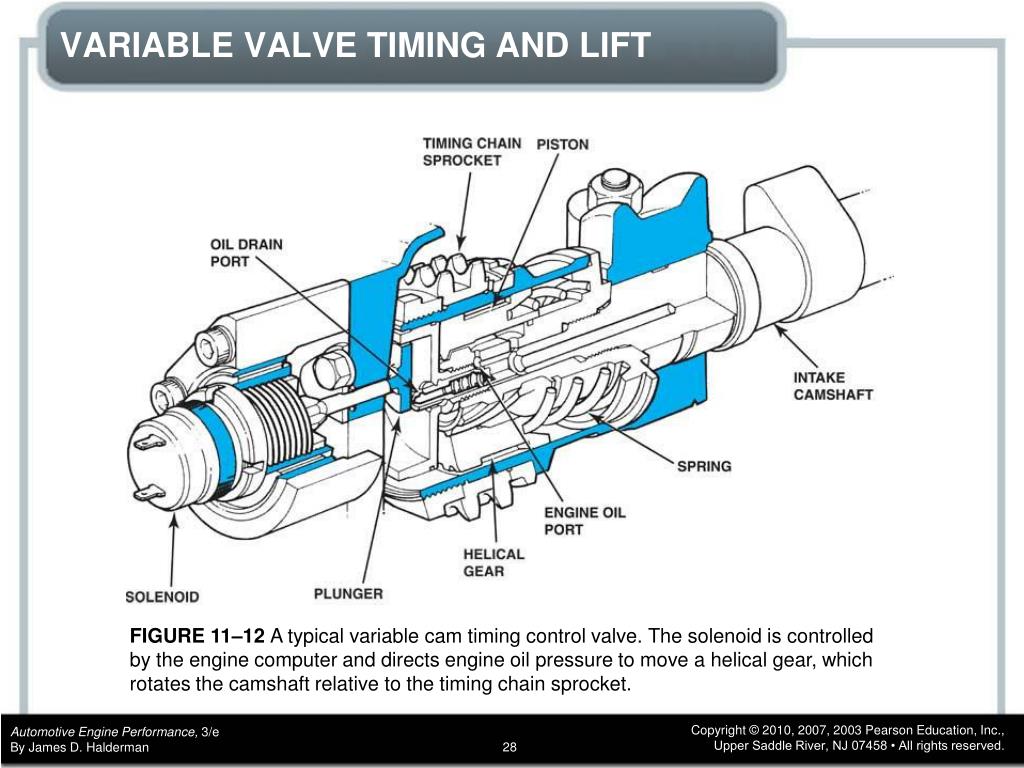

Variable Valve Timing and lift

Here, the principle is to use a two-position

advance or retard of either an engine’s intake or exhaust camshaft to better

match the engine’s operating conditions.

Two main factors that determine an IC engine

performance are

• The point at which valves open.

• The duration of the valves being open.

Types of Variable Valve Timing System

VTEC Engine (Variable Valve-Timing and Lift Electronic Control) VTEC works by varying valve timing and lift to compensate for the time delay and out-of-phase arrival of the air-fuel charge at the intake valve. Shifts valve between two separate sets of cam lobes — one for high-speed operation and one for low.

Advantages

·

Low fuel consumption appreciable increase in power

·

Lower tail pipe emission.

·

Valvetronic system, optimize engine power and

efficiency.

·

Reduces pumping losses

Disadvantages

·

Has a complex design to manufacture

·

Is expensive

·

High wear and tear occur

· Very difficult to maintain

Turbocharger

MK IV

Toyota Supra with sequential twin turbocharger producing 2500HP from Texas.

Picture Courtesy: The Drive

• A turbocharger is a turbine-driven forced

induction device that increases an internal combustion engine’s efficiency and

power output by forcing extra air into the combustion chamber:

• This improvement over a naturally aspirated

engine’s output results because the turbine can force more air, and

proportionately more fuel, into the combustion chamber than atmospheric

pressure alone.

• Turbochargers are commonly used on truck. car, train. aircraft, and construction equipment engines. They are most often used with Otto cycle and Diesel cycle internal combustion engines.

TURBOCHARGER

Working principle of Turbocharger

·

A turbocharger is a small radial fan pump driven by

the energy of the exhaust gases of an engine.

· A turbocharger consists of a turbine and a

compressor on a shared shaft.

·

The turbine converts exhaust to rotational force,

which is in turn used to drive the compressor.

· The compressor draws in ambient air and pumps it in

to the intake manifold at increased pressure, resulting in a greater mass of

air entering the cylinders on each in take stroke.

Advantages

·

The more increase the pressure of the intake air

above the local atmospheric pressure (boost), the more power the engine

produces.

·

Engines burn air and fuel at an ideal ratio of

about 14.7:1.

·

This is useful at high altitudes

Disadvantages

·

Cost and complexity

·

Detonation

·

Large space requirement

·

Turbo lag

Homogeneous Charge Compression Ignition (HCCI)

A mixture of fuel and air ignites when the

concentration and temperature of reactants is sufficiently high. The

concentration and/or temperature can be increased in several different ways:

· Increasing compression ratio

· Pre-heating of induction gases

· Forced induction

· Retained or re-inducted exhaust gases

Once ignited, combustion occurs very quickly. When auto-ignition occurs too early or with too much chemical energy, combustion is too fast and high in-cylinder pressures can destroy an engine. For this reason, HCCI is typically operated at lean overall fuel mixtures.

HCCI

Advantages

· They have a 30% higher

efficiencies than conventional SI gasoline engines.

· Cleaner combustion and lower emissions. NOx levels are almost negligible.

· HCCI engines can operate on gasoline, diesel

fuel, and most alternative fuels

· HCCI avoids throttle losses, which further

improves efficiency.

Disadvantages

· Achieving cold start capability.

· High heat release and pressure rise rates

contribute to engine wear.

· Autoignition is difficult to control.

· HCCI engines have a small torque range.

· Pre-catalyst emissions are higher than a typical spark ignition engine, caused

by incomplete oxidation.

The Future of Internal Combustion Engines

The invention of the internal combustion (IC) engine was a boon to

transportation and efficiency. But, as IC technology ages and environmental

concerns increase, alternatives are looking to take its place.

Automakers and consumers alike are mulling the future of internal

combustion engine production, and looking at what will replace the internal

combustion engine -- or what parts powder metallurgy (PM) got involved in.

Think about where PM has been used in an engine. Advances include

self-lubricating valve guides, connecting rods, variable valve timing, and so

on.

Looking at the background of what got us here, as well as new efficiency

and environmental challenges that powder metal could help solve, is a lesson no

engineer should miss.

1. Restrictions on CO2 Emissions

The Global Carbon Project reported that

worldwide carbon emissions reached an all-time high in 2018, with the number expected

to increase again for 2019.

The EPA published Greenhouse Gas Emissions guidelines

for passenger cars and trucks, with Phase 2 affecting model years through 2025.

Although the EPA seems to be rethinking some guidelines, it’s still

the political and environmental atmosphere that’s pushing internal

combustion engine efficiency improvements through, more so than consumer demand.

Whether engineers and executives personally agree

or not with the changes in the air, the industry is moving steadily in that

direction.

2. How to Increase Efficiency of IC Engine

Emissions?

The Office of Energy Efficiency &

Renewable Energy reports that manufacturers reduced pollutant

emissions by more than 99% over the last 30 years. Creative minds accomplished

this while still maintaining or increasing fuel economy.

In addition to gasoline and diesel, manufacturers

are studying other ways to increase fuel economy:

- Using

biodiesel

- Using

other alternative or renewable fuels

- Combining

IC engines with hybrid electric powertrains

3. Diesel Engines Vs. Traditional Gasoline Engines

When Europeans switched from diesel to gasoline cars,

there was a related increase in carbon dioxide emissions. In an unexpected

twist, some of today’s auto strategies are based around diesel engines.

Many big diesel trucks actually create less

CO2 emission than some smaller, gas-powered vehicles, reports indicate.

Increased technology has produced diesel-powered engines that can fuel

smaller vehicles and provide:

- Better

gas mileage

- Lower

carbon emission rates

- Greater

torque

- A

longer-lasting engine

4. Competing with Electric Engines

You knew this was coming. Although gasoline powered engines don’t

appear to be completely disappearing, they do face stiff competition from their

electric rivals.

While some see electric cars as the future, even BMW isn’t

backing away from the internal combustion engine just yet.

One thing IC engine supports could hang over the

heads of the pro-electric crowd was their battery. Specifically, its:

- Size

- Cost

- Longevity

- Charging

capabilities, or lack thereof

However, electric car prices are projected to

be competitive as soon as 2022 as

battery costs plummet. The battery was once about 50% of the car’s cost, but

could go as low as 20% by 2025. These reductions are certainly coming

more quickly than the market expected.

Concerns about range are less of an issue for

electric vehicles going forward. The technology is evolving, and more charging

stations are popping up. “Range anxiety” (consumer fear that they’ll be

stranded with nowhere to charge their battery) is still a very real issue OEMs

still need to resolve.

How The MGU-H and

MGU-K Work?

ERS stands for Energy Recovery System, and it is a fairly new innovation within the world of F1. First bursting onto the scene in 2009, it has evolved over time to become integral to the powertrains within the F1 cars.

The MGU-H uses excess

exhaust gases from the engine to feed power to the energy store, which is then

used to power the turbocharger’s compressor. The MGU-K feeds waste energy from

the decelerating wheels back to the energy store for later use.

Engine Size

Since 2014, the engines used in F1 cars

have been 1.6-liter hybrid V6s. These

are internal combustion engines, or ICEs, and they work using a traditional

4-stroke system you would find on your normal car. With a few extra components,

like special spark plugs and precise fuel injection

systems, it draws fuel and air into the cylinders, compresses

and ignites them, and discharges exhaust gases.

Where the powertrain differs from your

road car’s is in the power they can provide to the cars. They are capable of

more than 1000BHP, which is a massive

amount of power for a car that weighs less than a ton. The engine itself produces around 700BHP, with the

remaining power coming from the motor generator units that this article will

explain.

Energy Storage

These units generate and make use of

energy that is stored in an extra Energy Store (ES) or Energy Storage System (ESS), which is

essentially a large lithium ion battery. It is regulated to weigh between 20

and 25kg. They are also regulated with regards to how much energy they can

store and provide.

When deployed, the power boost

translates into totals of around 300BHP for around 30 seconds

each lap, which is obviously of massive advantage to the

drivers. The MGU-K is used to harvest “waste” energy from the wheels under

deceleration and provide this to the energy store to be used later. The MGU-H

works in a similar way, although it is linked with the turbocharger.

The MGU-K can harvest 2MJ per lap and deploy

4MJ per lap, while the MGU-H can harvest an unlimited amount, but only deploy

2MJ per lap. Energy

from the MGU-H can either be used to power the MGU-K or sent to the Energy

Store.

5. Powder Metallurgy Supports the Move to

Eco-Friendly

Powder metallurgy is becoming more of a factor in

component design for engines, whether IC engine designers like it or not.

The “green” technology that is powder metallurgy

goes hand in hand with the future of the eco-friendly automobile. Sintered soft

magnetic materials with higher densities are providing a boost in performance

not seen before. You may have heard the story of powder metal before, but these

new materials are different from the Standard 35 materials that

manufacturers have relied on for decades.

MPIF’s Standard 35 is a great baseline for powder

metallurgy manufacturers, but your future designs may need materials and

processes that surpass “standard” performance levels. In some cases, you can

even eliminate a component from the assembly by designing with powder

metal.

Today’s advanced compaction technology may be a

little more expensive at the onset, but it can save manufacturers (and drivers)

a lot in the long run.

Many components can be transitioned to powder

metal. Powder metallurgy has made great advances in creating small parts

for electric motors and

other auto parts for many reasons:

- Reduces

weight.

- Improves

electric motor efficiency, including better magnetic properties.

- Creates

net-shape parts.

- Allows

for advanced materials and processes.

- Higher

strength and hardness

Specifically, soft magnetic

composite materials are leading the way toward a super-efficient electric

motor.

Powder metallurgy is not just rods and end caps any

longer!

Where Will You Turn Next?

Today’s

powder metallurgy services allow for a smooth transition from the traditional

internal combustion engine design to the more efficient and environmentally

conscious engines of the future. Advances in PM materials and processes

(like sintering) have made that possible.

Of

course, internal engines will still be around for a long time. Powder metal can

still bring significant benefits to IC engines too.

As closing statements, I

would like to say internal

combustion engines are among the most important engineering applications. The

theory of application either depends on Diesel or Otto cycles. They are

categorized either according to the operating cycle, or due to the mechanism of

working. Although the world is marching towards hybridization and

electrification, ICs are still sought being developed to make the vehicle

faster and more efficient.

BY:

Students of

Vishwakarma Institute of Technology

Digvijay Gaikwad- digvijay.gaikwad18@vit.edu

Yashraj Desai- yashraj.desai18@vit.edu

Kunal Deshmukh- kunal.deshmukh18@vit.edu

Sanket Gaikwad- sanket.gaikwad18@vit.edu

Umesh Gaikwad- umesh.gaikwad18@vit.edu

References:

www.gaukmotors.co.uk

www.wikipedia.org

greenyflat.com.au

www.evo.co.uk

https://www.horizontechnology.biz/blog/future-of-internal-combustion-engine-design-trends

https://www.sciencedirect.com/science/article/pii/S1877705815008425

Informative 👍

ReplyDeleteBlog is informative , really good work

ReplyDeleteInformative

ReplyDeletePathbreaking 👍🏻

ReplyDeleteShort and precise, great content

ReplyDeleteThis comment has been removed by the author.

ReplyDeletegood blog

ReplyDeleteNice Info ...!!

ReplyDeleteNice one 🔥

ReplyDelete